Engraving leather is an artisan art that can be learned by everyone, thanks to which it is possible to decorate any leather object, from the belt to a riding saddle. It is a process of scratching the material according to specific shapes and designs. There is another leather decoration technique that goes hand in hand with engraving: printing. If you are just approaching the world of leather processing, this article will help you learn the basics of obtaining a beautiful finished product. Start reading!

Steps

Part 1 of 4: Choosing and Buying Leather

Step 1. Find a good leather supplier

There are many "physical" and online shops to turn to or you can look for some tannery in the area that could sell you some scrap pieces (or maybe give them away) on which you can practice!

Step 2. Learn about the leather market

When looking for a good store you need to evaluate how they sell the product. Good quality pieces are usually offered by the square meter or in pre-cut batches. In some cases, scraps and trimmings are available which are offered by weight. If you feel that they are selling you the product in an unusual way, try to be vigilant.

Step 3. Check for scars, insect bites and marks

Not only will these elements make the engraving process more difficult and the finished product uglier, but they are also a sign that the leather seller is in turn buying the raw material from companies that treat cows terribly. You certainly don't want to be complicit in animal abuse, so only turn to reputable suppliers.

Step 4. Start by purchasing cheap, beginner-friendly pieces

Writers have to write and rewrite hundreds of thousands of words before they are satisfied; the same goes for leather processing: you will have to make several bad engravings before you see a good result, so don't buy particularly valuable pieces. Buy waste by weight or another similar product. When you are ready for something of better quality, you will notice it.

Step 5. Buy the right type of leather for engraving

It must be tanned with vegetable products to obtain a good result. The other types of leather adapt to different processes, but for the engraving entrusted to bovine leather tanned with vegetable products.

Avoid pieces intended for the production of furniture or those that have surface workings, they are not suitable for engraving

Step 6. Choose the thickness

Each project requires leather of different thickness, make sure the one you purchased is suitable for your purposes. The thickness is measured in millimeters, although it is not uncommon to find in the leather market with values expressed in the Anglo-Saxon system. A 2-3 ounce patch, for example, is too thin to cut, start with one that is at least 3-4 ounces or more.

If you want to make sure with a gauge of the exact thickness in millimeters, know that the best first grain leather has a thickness of 1, 8-2 mm

Part 2 of 4: Choosing and Using Tools

Step 1. Buy a set of tools to get started

There is no reason to immediately get all the tools of a professional by spending a fortune. The ideal is to buy a beginner set because each craftsman engraves differently and what works for one is not as good for another. You must have the freedom to try. You can get a small kit for a reasonable price online.

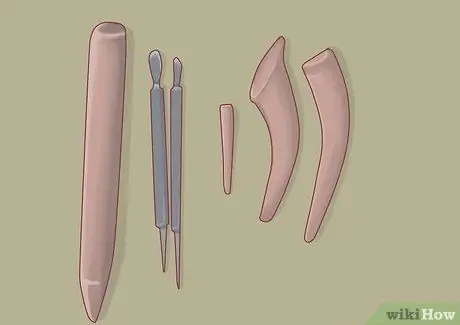

Step 2. Consider buying modeling tools as well

Although they were designed for clay, they are also useful in leather processing. Spatulas and mirette are among the most used.

Step 3. Prepare the work base

You should never cut, engrave and scrape the leather on a surface that has veins (or on a table that you care about and do not want to damage) to prevent the design of the base from transferring to the leather. You should use a granite or marble cutting board that you can get from some marble worker or construction company; sometimes you can also find a scrap piece but useful for your purpose.

A rubber mat helps you muffle the noise and holds the marble base in place

Step 4. Get a mallet

This is a tool that you will use for almost any type of engraving. It is recommended to start with a polycarbonate one, never use a metal hammer and avoid wooden ones (they are too delicate). There are also some raw leather mallets but they are expensive, so it is best to wait until you have done some practice before investing a lot of money.

Step 5. Focus on the most important tools

If you have to buy them individually, target the basic ones, the most useful. You will need to get yourself a punch, a revolving knife, some sights, an awl, a mallet and some molds.

Step 6. Check that the tools are the right size

They come in different sizes, but the standard ones are fine for large, men's hands. If you are a woman or a young boy and have small hands, choose the size that suits you and does not complicate your work.

Step 7. Understand the language of leather decoration

The traditional molds and forms of leather engraving are defined with a unique jargon. Most tools have a name that might seem nonsense, but most of them refer to a very specific object designed for an equally specific purpose. Learning the names of these tools will be very useful both for understanding the instructions you will find online and for buying the right tools.

Step 8. Don't feel constrained by the common use of a tool

Engraving leather is exactly like sculpture: there are many tools available and everyone uses them as they see fit. Don't think you are wrong just because you use a certain mold to get a type of decoration, even if this was meant for something else. Anything that suits your purpose and works is fine.

Part 3 of 4: Creating the Engraving

Step 1. Print the decoration

The simplest and cheapest way to find the motif you want to transfer onto the leather is to print it normally, from home. You can also trace the design on glossy paper or baking paper. However, you should never use carbon paper or write directly on the leather.

This is an optional step as you could use the freehand engraving tools directly on the leather to create the decoration

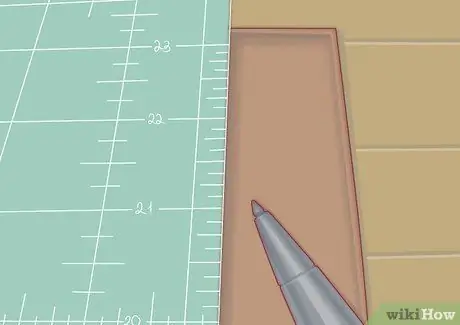

Step 2. Cut out the piece

Cut the leather to obtain the final shape of the object you need to decorate (in the shape of a belt if this is the one you need to engrave, or a large rectangle if you need to embellish the side of a saddle). Never use scissors to cut this type of leather. Scissors are used only on very thin skin, almost like fabric. You have to rely on a cutter.

Step 3. Moisten the skin

This doesn't mean you have to put it under running water; although ordinary water may be suitable, it is better to rely on specific solutions (which you can find in leather and leather stores or online) that allow you to protect the piece from water stains. Simply apply the liquid of your choice to the leather using a sponge or spray bottle.

- Don't overdo it, the leather must not soak.

- It is usually not necessary to wet a section more than once. If you have to stop for some reason, wrap the piece you are decorating in cling film and store it in the refrigerator.

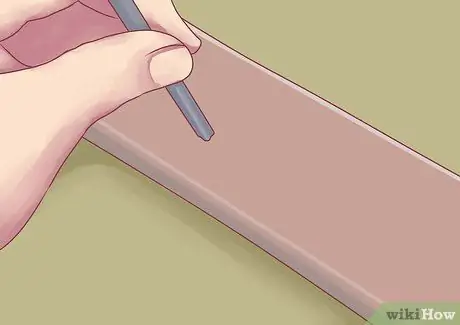

Step 4. Trace the design into the leather

Wait for it to start returning to its original color and start tracing the design. Line up the pattern you printed with the leather patch and use a blunt pencil or clay stick to “trace” the design. Do not press too hard, lift the sheet of paper and you will see that the liquid has allowed your slight pressure to temporarily affect the leather.

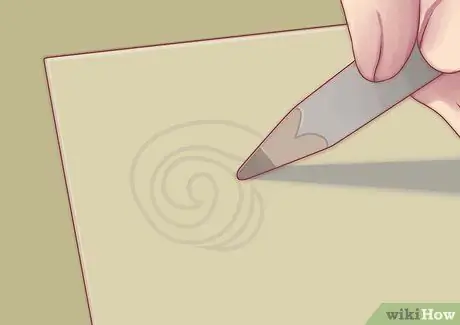

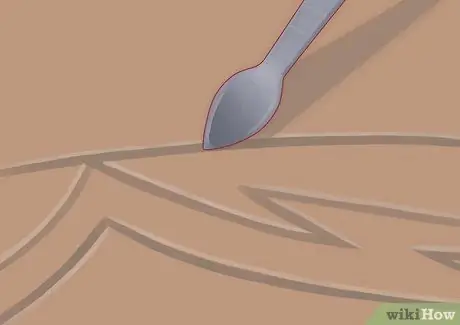

Step 5. Cut the main lines with a revolving knife

At this point you have to go over the provisional drawing with this tool. Grab it as if it were a pen with your thumb and middle finger on the sides and your index finger in the middle. The blade should be straight down, press the back corner into the skin. Then pull the blade towards you while keeping your wrist straight and rotating the blade with your fingers to follow the lines of the design.

- The blade must always be pulled towards you to be able to adjust the position according to the drawing.

- It's a great idea to spend a lot of time training with this tool on scrap pieces before starting a real project. This helps you learn how to move the blade to get the design you want.

- You can change the speed, pressure and length of each incision to achieve different effects. For example, short and quick cuts make the idea of fur.

Step 6. Decide which sections should appear in high relief and which ones should appear in low relief

Once you have engraved the main lines, you need to decide which sections will stand out from the background. You also need to evaluate the shading or the surface pattern. Plan your drawing with a sketch in advance for a professional-looking result.

Step 7. Emboss or smooth edges to make the design stand out

You can use tools such as clay sights to squeeze the edges of the design so that the nearby surface is embossed. Make sure you do a consistent job across the entire surface you set out to stand out!

Step 8. Use the molds to create designs or to add shading

Place one on the leather evenly and hit it with 1-2 mallet blows to transfer the image. Practice on scrap pieces first until you understand how to get exactly the effect you want.

- Don't hit the mold hard because you don't have to crack the surface of the leather so that you can see the inner layers. The hammer must be held with a firm but soft grip to allow it to bounce.

- When engraving, try to print the skin only once per section. Sometimes very large molds require two or more mallet strokes. In this case, align the mold again according to the previously drawn lines and hit it again.

Step 9. Press the leather if necessary

When large patches of leather are cut, they can start to crumple. To prevent this from happening, when you are done, you should press the leather as it dries so that it takes the correct shape. You must not use any objects that are too heavy and avoid that the surfaces have a decoration that can transfer to the leather.

Part 4 of 4: Final Touches

Step 1. Smooth the corners

Use the right tool to remove the sharp edges of the leather patch, so they won't curl in the future. You only need to perform this procedure on one side of the leather - the back must remain flat. Be very careful with sharp corners, these will be rounded off separately by creating a diagonal or cutting the corner.

Step 2. Add the finishing touches such as the tint

Once the edges have been smoothed out, you can consider adding as many embellishments as you like. You can make an area stay lighter or darker, just be sure to use gloves when using dyes and finishing products… unless you want a different color coat!

- On the market you can find many types of finishes with a wide range of colors. To apply them you can use kitchen paper, a wool pad or a very old natural sponge (do not use synthetic ones because they contain substances that react with leather).

- You can also use dyes. There are many specifics for leather, but sometimes you can also use simple shoe polish! They must be applied just like the finishes.

- Water-diluted acrylic paints are great for skin if you prefer vivid colors. Use a normal brush to apply them; they look great in small and highly detailed decorations.

Step 3. Feather the edges

Once you have applied the dyes, you can blend the edges with a specific tool (smudge) or simply with a piece of kitchen paper or a jute cloth. This will give it a professional touch and the work will have a finished look.

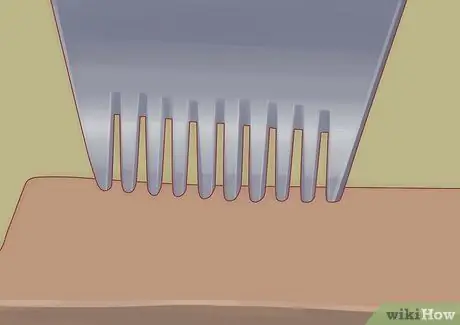

Step 4. Drill holes for the seams

If you expect leather to be sewn, you can drill holes to prevent the stitches from wearing out over time. In this regard, you can use the special tool called the punching pliers. You must first create a "channel" where the various points will be inserted (so they will remain well aligned) and then proceed to the actual drilling. This detail will also give a professional look to the work.

- When buying a die cutter, choose a short one as it is more versatile and allows you to follow corners well.

- When you draw a new line for the stitches or you need to start following it with the die cutter, put the first punch in the hole of the last section of the line to keep the holes evenly spaced.

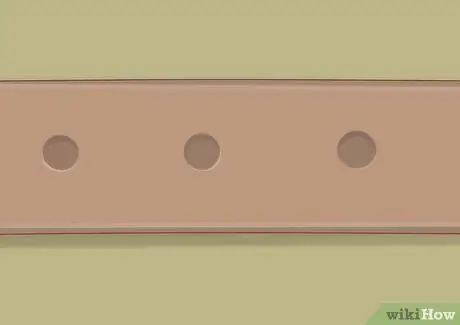

Step 5. Add more details

Before sewing, you need to add other details such as snaps. However, be aware that this is a complicated procedure and requires a separate set of tools. When this step has also been completed, add the seam and you are practically done. Rub the entire surface with a cloth to smooth and polish the leather.

Step 6. Apply a gloss or clear finish if desired

This is the last detail you can add after sewing. This is not a mandatory step, however. Enjoy your new leather creation and keep practicing!

Advice

- Once you've mastered it, you can smooth the edges to add dimension to your design. You will use these tools slightly to the right or left, instead of hitting the leather perpendicularly.

- You can polish the leather after wetting it, before starting to work it. It could serve to better hold the drawing. You can find a polishing tube at a home improvement store.

- Buy books about these techniques or check the library if you want to learn how to make complex drawings. Practice with simple projects before moving on to difficult ones.