Singer products range from simple sewing machines for beginners to complex and technologically advanced tools used by professionals and amateurs. Home sewing machines have a threading guide at the top and the type of guide determines how the machine is threaded. This article describes how to thread a two-part guide and single guide machine.

Steps

Step 1. Determine what kind of car you have

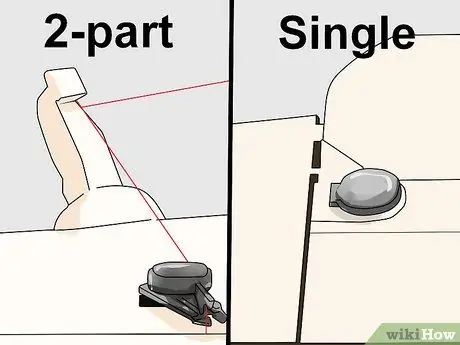

No matter the year of manufacture, the most common Singer machines have a threading guide that falls into one of these two categories:

- A two-part slide is made from a small piece of metal and a larger plastic piece placed on top of the machine. The thread is passed through both of them before continuing down towards the needle.

- A single-piece guide, on the other hand, is made up of a single metal piece always placed on top of the machine.

Method 1 of 3: Thread a Two-Part Guide

Step 1. Turn off the machine

Make sure there is no power connected to the machine before starting threading. You risk injuring yourself or damaging the machine.

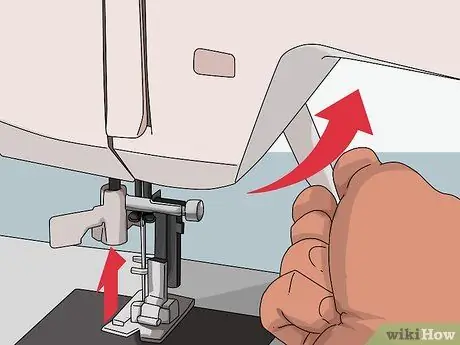

Step 2. Raise the needle as high as you can

Turn the hand wheel towards you to raise the needle.

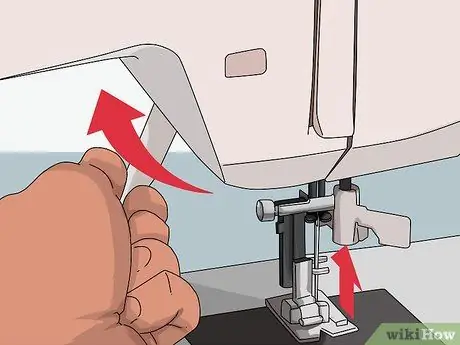

Step 3. Raise the presser foot

Grab the handle on the side to raise the presser foot to pass the thread through the stitches.

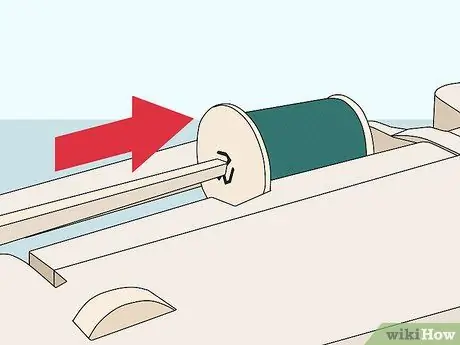

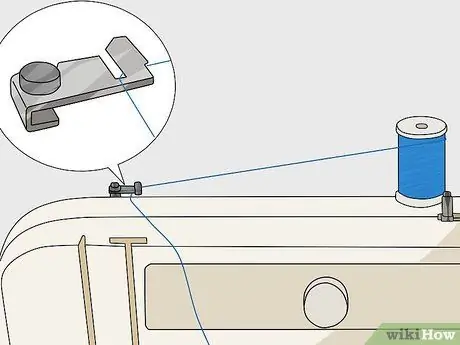

Step 4. Put a spool of thread on the spool

Some machines have vertical spools and others horizontal. Either way, put a spool of thread on the spool.

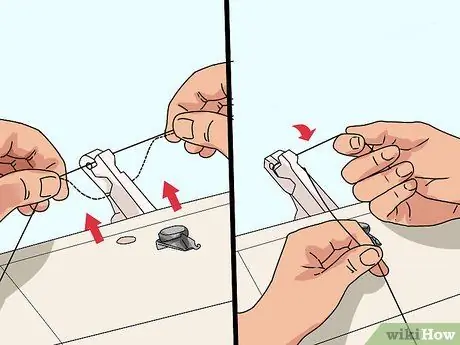

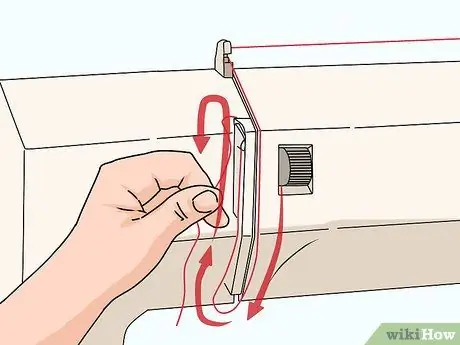

Step 5. Pass the thread through the first guide

First pass it through the lower opening and then through the upper one. Pull the thread to the right and then pull it.

Step 6. Pass the thread through the second guide

Pass it to the right and under the guide so as to insert it from the bottom up.

Step 7. Pass the thread through the tensioner

Guide it through the threading channel until it hooks onto the tension discs.

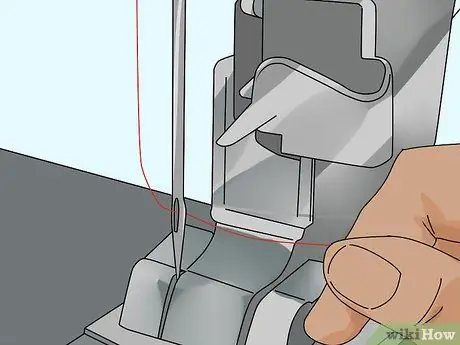

Step 8. Thread the eyelet

Pass the thread under the hook and inside the eyelet where it will remain in place.

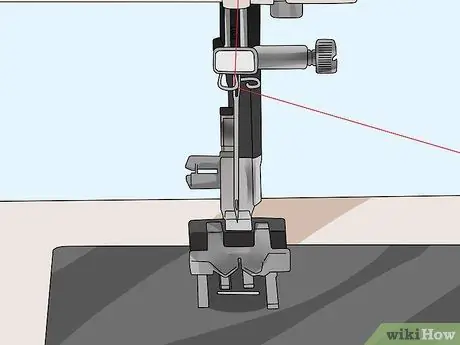

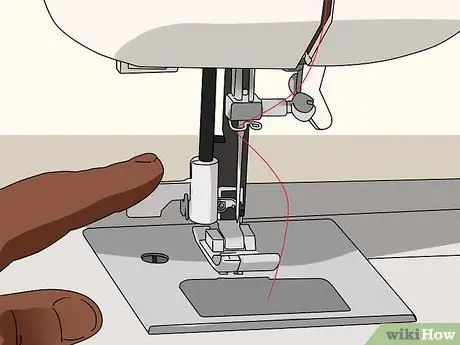

Step 9. Thread the guide just above the needle

It is a small hook that holds the thread in tension. Some machines above the needle have more than one guide for this purpose.

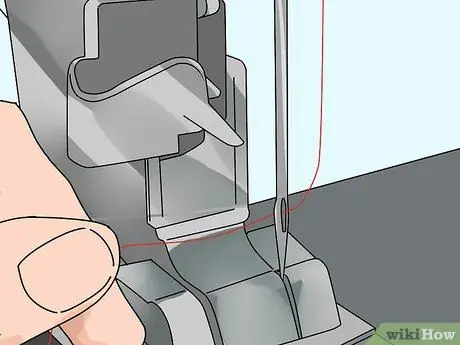

Step 10. Thread the needle

Pass the yarn from front to back.

Method 2 of 3: Thread a Single Guide

Step 1. Turn off the machine

Unplug the machine from the power outlet so you don't accidentally turn it on while threading.

Step 2. Put the needle in the highest position

Turn the wheel towards you until the needle is up to the maximum.

Step 3. Raise the presser foot

Take the handle on the side of the presser foot and raise it.

Step 4. Put a spool of thread into the spool

If your machine has a horizontal spool, put a stop on it to hold it in place. If it is vertical, leave the coil as it is.

Step 5. Pass the thread through the guide

Pull it to the left of the guide and pass it under the hook and inside the insert.

Step 6. Pass the thread around the tensioner

Guide the thread through the threading channel and hook it onto the tension discs.

Step 7. Thread the eyelet

Pass the thread under the hook and inside the eyelet where it will remain in place.

Step 8. Thread the guide just above the needle

It is a small hook that holds the thread in tension. Some machines above the needle have more than one guide for this purpose.

Step 9. Thread the needle

Pass the yarn from front to back.

Method 3 of 3: Prepare to Sew

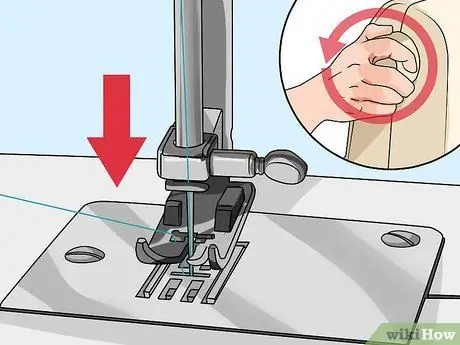

Step 1. Lower the needle

Pull the end of the thread through the needle so that you have a few centimeters. Turn the wheel towards you until the needle is no longer visible and is completely inside the bobbin.

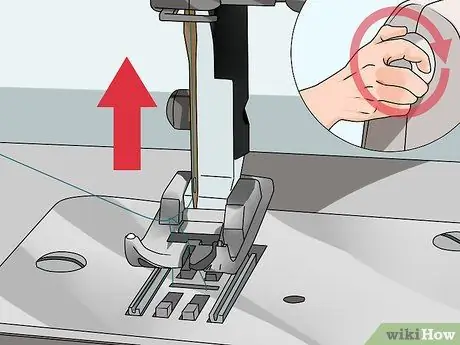

Step 2. Raise the needle

Slowly move the wheel until the needle reaches the highest possible position again. During this phase it continues to hold the thread that passes through the needle. When the needle comes up, the bobbin thread ring will also come up.

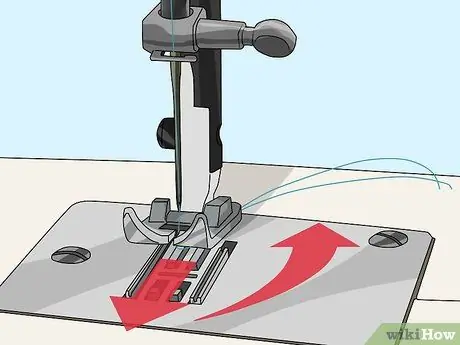

Step 3. Arrange the thread

Pull the thread towards you until the ring is off the bobbin. Pull both parts of the thread until they are under the presser foot. Put the end of the thread behind and to the right of the sewing machine.