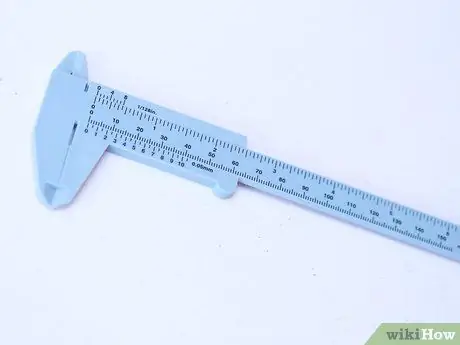

Calipers are measuring tools used to accurately determine the width of a crack or object and are much more accurate than a tape measure or ruler. In addition to the digital models, which show the readings on a display, there are the Vernier calibers that use one or two measuring scales and finally the dial calipers.

Steps

Step 1. Identify the type of gauge

Use the instructions in this section about the Vernier gauge, if your instrument has two scales that slide over each other. If, on the other hand, the caliber has only one scale and a round dial, then read these indications on the dial caliber.

If you are using a digital caliper, the readings should appear on an electronic display, which can typically be set in millimeters or inches. Before starting to measure, make sure that the two main jaws are perfectly closed and press the Zero, Tare or ABS keys to zero the instrument

Method 1 of 2: Vernier Caliber

Step 1. Check that the instrument is well calibrated

Loosen the screw or screws that secure the sliding ladder. Move them until the main jaws are perfectly closed. At this point, make sure that the zero mark on the sliding scale is exactly aligned with the zero mark on the fixed scale which is engraved on the body of the gauge. If the zeros coincide, then go directly to the section of the article with the reading instructions; if not, continue reading the next step.

Reset the instrument

Step 1. If present, use the setting wheel

Although not a very common accessory, sometimes Vernier calibers are equipped with an adjustment wheel on the sliding scale. This allows you to change the position of the scale without altering that of the beaks. If your instrument has this wheel, push it until the zero mark on the sliding scale is perfectly aligned with the zero mark on the fixed scale. You can move on to this part of the article later. If not, read the instructions below.

Watch the jaws to make sure you don't push the fine adjustment screw, which opens and closes the jaws in very small increments

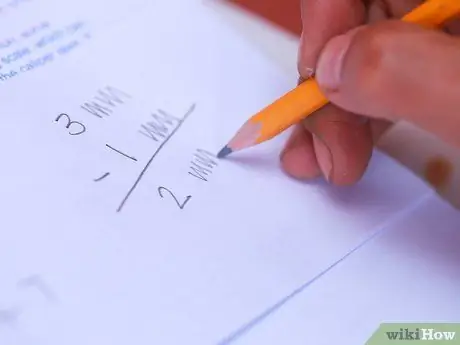

Step 2. Calculate the positive calibration error

If the zero of the sliding scale is at right than that of the fixed scale, read on the latter the value of the notch to which the zero of the sliding scale aligns. This is the positive error and you need to write it down with a + sign.

Eg, if the zero on the sliding scale lines up with the 0.9mm mark on the fixed scale, you need to note a "+0.9mm" error.

Step 3. Calculate the negative calibration error

If the zero of the sliding scale is at left zero of the fixed scale, follow these instructions:

- Close the jaws of the tool and look for a notch on the sliding scale that is perfectly aligned with one on the fixed scale.

- Move the sliding scale until this notch lines up with the next higher value. Repeat the process until the zero of the sliding scale is to the right of the zero of the fixed one. Note the value of the displacement.

- Read on the fixed scale the value of the notch that aligns with the zero of the sliding scale.

- From the value just read, subtract that of the displacement you noted earlier. Make a note of the result accompanied by a negative sign.

- For instance, the 7 on the sliding scale lines up with the 5 mm mark of the fixed one. Move the slider until it is more to the right than the fixed one and then align the 7 "slider" with the next value on the fixed scale: 7 mm. Note the displacement which is 7 - 5 = 2mm. The zero of the sliding scale is now at the 0.7mm mark. The negative calibration error in this case is 0.7mm - 2mm = -1.3mm.

Step 4. Subtract the calibration error from all measurements you take

Every time you measure an object, remember to remove the error value to get the real size. Don't forget to take into account the sign of the error (+ or -).

- For example, if your error is +0.9mm and the measurement you just took gives a reading of 5.52mm, then the actual size of the object is 5.52 - 0.9 = 4.62 mm.

- If the calibration error is -1, 3 mm and the measurement shows a value of 3, 20 mm, in reality the object has dimension 3, 20 - (-1, 3) = 3, 20 + 1, 3 = 4, 50 mm.

Read the Measurements

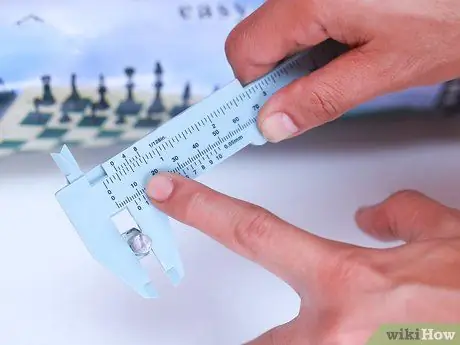

Step 1. Change the width of the beaks to detect the size

It "grabs" the object with the vice created by the two flat beaks, so as to detect its external dimensions. For internal dimensions, insert the two smaller, curved beaks and spread them out until they rest against the walls of the object. Close the setscrew to lock the gauge in this position.

Slide the ladder to open or close the beaks. If your instrument has a fine adjustment screw, you can use it to make fine adjustments

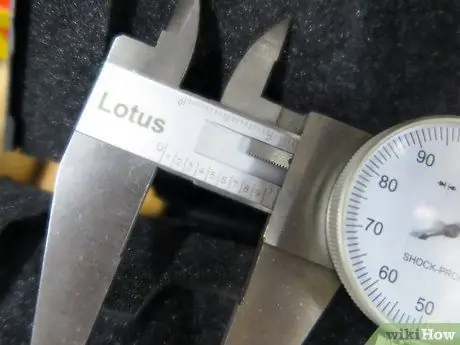

Step 2. Read the value on the fixed scale

When the beaks are in the right position, look at the fixed scale that is engraved on the body of the gauge. You generally find both the metric scale and that of the British imperial system; you can use whichever you prefer. Follow these instructions to find the first two digits of the measurement value:

- Find zero on the smallest scale, the sliding one, which is next to the fixed one.

- On the fixed scale, find the notch that lines up with the zero mark on the sliding scale or is immediately to its left.

- Read the value of this notch as you would with a ruler; however, remember that the British imperial scale in this case is divided into tenths of an inch and not sixteenths as is the case with most rulers.

Step 3. Check the sliding scale for the other digits

Observe it carefully starting from zero and moving to the right. Stop when you come across a notch that lines up exactly with another engraved on the fixed scale. Read the corresponding value on the sliding scale as you would a ruler using the unit of measurement indicated on that scale.

The value of the mark on the fixed scale does not matter, you only have to consider that of the sliding scale

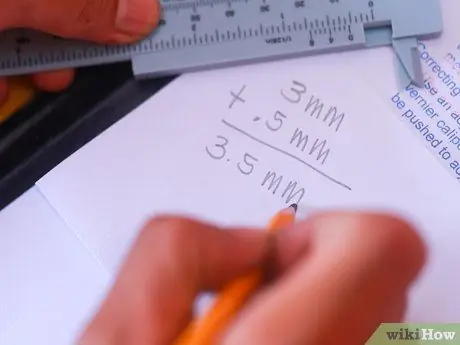

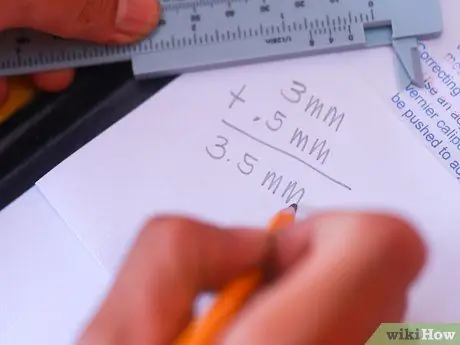

Step 4. Add the detected values together to find the size of the object

This is a simple operation, just write the digits of the first value you noted down, that of the fixed scale, followed by those you read on the sliding scale. Always check the unit of measurement that is engraved on the instrument so as not to get the calculations wrong.

- For example, the value shown on the fixed scale is 1, 3 and is expressed in "inches". The value you found on the sliding scale is 4.3 and this is expressed as "0.01 inch", which means that this number represents 0.043 inches. The exact measurement is 1.3 inches + 0.043 inches or 1.343 inches.

- If you previously calculated a calibration error, don't forget to subtract it from this final measurement.

Method 2 of 2: Dial Caliper

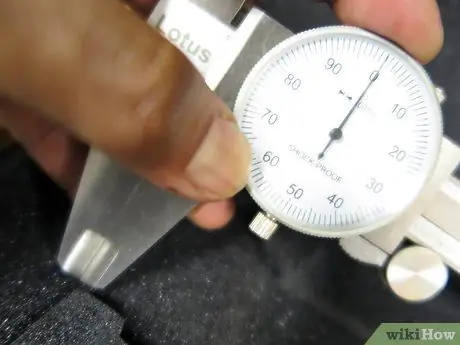

Step 1. Check the calibration error

Shut your beaks completely. If the needle does not point exactly to zero, rotate the dial with your fingers until it does. You may need to loosen a screw above or below the dial before you can rotate it. If so, remember to re-tighten it when you're done.

Step 2. Take the measurement

Close the large, flat jaws around the object to measure its outer diameter or width; to detect the internal dimensions, insert the small, curved beaks into the object and then spread them apart.

Step 3. Read the value on the scale

This is engraved on the body of the gauge and can be read like a normal ruler. Find the value that is on the inside edge of the beaks.

- The scale should also show the unit of measurement, usually centimeters (cm) or inches (in).

- If inches are reported, remember that gauges follow the engineering scale, i.e. each inch is divided into tenths (0, 1) or fifths (0, 2) and not sixteenths or eighths, as with rulers.

Step 4. Read the value on the dial

The needle should indicate another value which makes the measurement even more accurate. The unit of measurement is indicated on the face of the dial, usually in hundredths or thousandths of a centimeter or inch (0.01 or 0.01).

Step 5. Add the values

Convert both data to the same unit of measurement and then add them together. For most uses you shouldn't need the figures that indicate greater accuracy.

For example, the fixed scale indicates 5, 5 and is expressed in centimeters. The needle indicates the value 9, 2 and its scale is calibrated in 0, 001 cm, so the final value is 0, 0092 cm. Add the numbers together and you get the measure of 5, 5092 cm. Unless you're working on a project where maximum accuracy is a must, you can round this value to 5.51cm

Advice

- If you have trouble reading Vernier or analogue caliber, buy a digital one.

- To reduce the possibility of error, store the caliper with the jaws slightly open. Clean it regularly to remove dust and grime that accumulates between the beaks by rubbing it with alcohol or white spirit.